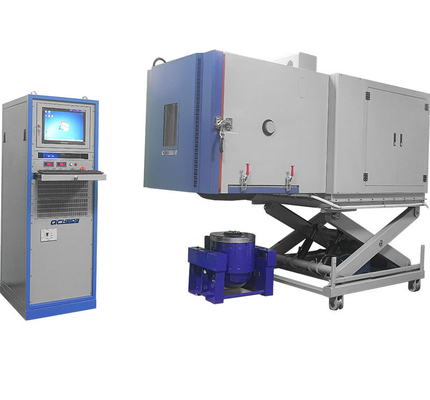

Characteristics:

Ultra mute work; The machine base uses the high quality material, installs conveniently, the operation is smooth, does not need to install the The, the control circuit digitization control and the display frequency, the PID adjusts the function, causes the equipment work to be more stable, reliable, sweeps the frequency and the fixed frequency operation way, adapts to the different profession test request To solve the interference of the strong electromagnetic field to the control circuit, and to increase the working time set, so that the test product reaches the accurate test time.

How to use:

1, the control manual to complete the procedure

2, such as Operation error so that can not work, you can use the recovery method of the steps of the input, and then set a single group or other running steps.

3, before use to press the external start switch, appears COO namely lets go, opens the key.

4, Taiwan Body:

1 The table body foot sleeve as far as possible fixed

2 power supply on/work in the output line can not be unplugged

3 Place the level as far as possible

4 components can be changed, the line should not be changed or from the connection.

5 The Taiwan body must not be all or part of the reorganization, only according to specifications for a single component and with the original confirmation password.

5, the amplitude inside the code

1. Do not adjust too large before or after the boot

2) low-key amplitude of high amplitude modulation

3 Control Panel Amplitude Knob placed in the middle position test items: placed to focus on the main point, reduce the left flat right.

4 control Box: Can not be placed on the top or underground operation

6, Inside Code:

1) reset when running or operating incorrectly

2) Control The Reset method step, each inside code only set one time to save can

3 usually must use the internal code can not be set randomly

7, Control Box:

1) The connecting line of the body must be locked tightly after hanging

2 the vibration direction switch and the output connection line are correspondence, can not connect the wrong

8, testing: Non-special test should use full wave test

9, the Taiwan body: can not produce the collision sound, the upper and lower center axis mutual touch will cause the spring steel piece rupture to be immediately shut down, amplitude modulation is adjusted small then turns on.

10, other unknown:

Do not arbitrarily change internal components and lines

11, the reason is bad:

1 The use of computer models can not be used for shaking table control

2 can not reload the driver

2, for the Ista-ia test, the operator to protect the sample, to prevent the test pieces slide out of the table;

3, gear gearbox replacement regularly;

4. Cut off all power when not working, keep clean; 5, non-staff can not operate at will

After-Service:

Should any issues arise during your testing process, we guarantee:

Timely Response: A formal reply within 48 hours.

Swift Resolution: A proposed solution within 3 working days.

Comprehensive Support: Access to English operation manuals, instructional videos, and video conference assistance.

Why Choose Us?

Global-Ready Design

Built-in voltage auto-switching (110V/220V), international plug compatibility, and safety-certified indicator protection.

Exceptional After-Sales Support

18-month comprehensive warranty. Industry-unique benefit: Complimentary repair service for controllers – even competitor units. Simply ship the controller to us.

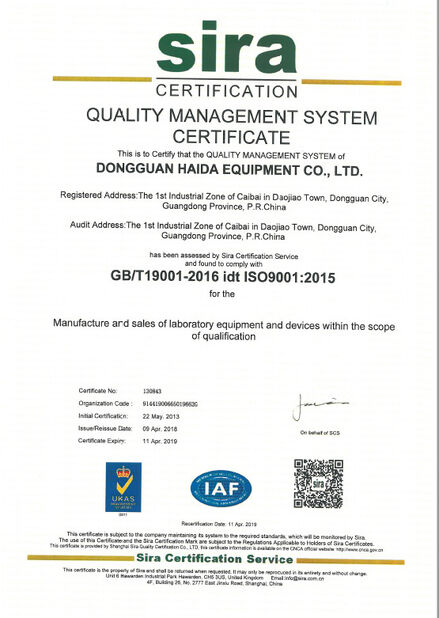

Binding Quality Commitment

A formal Quality Assurance Letter accompanies every contract signing, guaranteeing performance and building trust.

Industrial-Grade Protective Packaging

(e.g., Triceratops) is individually wrapped in anti-static bubble film and secured in reinforced wooden crates. This ensures:

• Shock absorption & impact resistance

• Moisture & corrosion protection

• Non-toxic, odorless materials

• Optimal transparency for inspection

FAQ:Q: Are you a trading company or manufacturer?

A: Integrated manufacturer with 21+ years specializing in test equipment and 6 years of export expertise.

Q: What is your delivery timeline after order confirmation?

A:Standard orders: 10-25 working days

Stock orders: Ship within 3 days

Note: Lead times vary by product specifications and order volume.

Q: What are your warranty and after-sales service terms?

A:12-month comprehensive warranty on all testing machines

Industry-unique benefit: Complimentary controller repairs (including non-HAIDA units)

Post-warranty support: Dedicated technical team for troubleshooting, operational guidance, and complaint resolution

Q: How do you ensure product quality and service?

A:100% pre-shipment inspection with full performance testing

Global-ready design: Voltage auto-switching (110V/220V), international plugs, safety-certified indicators

Multi-tier training support:

✓ Instructional operation videos

✓ On-site engineer training (upon request)

Market-proven reliability:

Globally recognized by industrial users

Q: Do you offer product customization?

A: Yes, we develop tailored solutions based on your technical parameters and application requirements.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!